|

Applications

Sophisticated manufacturing

and assembly environments such as Class 350 cleanrooms require the installation

of HEPA filters at the point of air entry to the room. This requirement

is set out in Australian Standard AS1386, Cleanrooms and clean workstations,

and the Code of Good Manufacturing Practice for Therapeutic Goods – Medicinal

Products published by the Department of Community Services and Health,Typical

cleanroom applications include the manufacture and packaging of sterile

pharmaceuticals, medical devices and electronics components.

Description Description

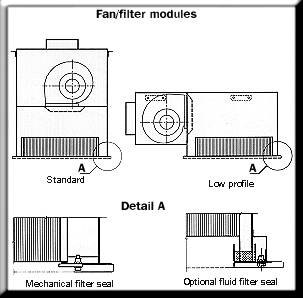

TFP modules are terminal

HEPA filter plenums designed for ceiling installation in new cleanroom

construction, or for upgrading existing rooms. Modules are suitable for

use in ceilings of plasterboard or laminated-panel construction, and are

supplied with fittings to facilitate installation.A range of configurations

and sizes enables the system designer to select modules for any application.

Low-profile modules are recommended for installations where ceiling space

is restricted.Fan-assisted modules have been developed for applications

where the existing air supply system does not have the fan capacity to

overcome the additional static pressure of HEPA filters. Variable-speed

fans enable airflows to be regulated to meet requirements for room pressure

and airflow, and to compensate for filter dust loading.

Construction

Housings.

Constructed in electro-galvanised steel with exterior finish in a special

baked enamel that has been developed for cleanroom and laboratory equipment.

Standard modules use a mechanical (gasket) filter seal, with the option

of fluid seal available on some models.Access on the underside of the module

(room side) for filter and fan service, an aerosol sample port and fan

speed controller obviates the need for access to the ceiling space.Pre-drilled

brackets are provided to facilitate suspension arrangements. Housings.

Constructed in electro-galvanised steel with exterior finish in a special

baked enamel that has been developed for cleanroom and laboratory equipment.

Standard modules use a mechanical (gasket) filter seal, with the option

of fluid seal available on some models.Access on the underside of the module

(room side) for filter and fan service, an aerosol sample port and fan

speed controller obviates the need for access to the ceiling space.Pre-drilled

brackets are provided to facilitate suspension arrangements.

HEPA filters.

Clyde-Apac

Microseal™ HEPA filters are manufactured to the most exacting standards

for critical applications. Each filter is individually certified to achieve

an arrestance efficiency of not less than 99.995% to the stringent BS3928

Sodium Flame test. All testing is conducted in a NATA-registered factory

laboratory and a NATA-endorsed test label, being an extract of the test

report, is affixed to each filter. A perforated metal guard, secured with

quick-release fasteners, protects the filter from mechanical damage, and

presents an attractive appearance to the room.

Fans.

Direct-drive fans with manual

speed controllers are used on fan-assisted units.

Electrical.

Fan-assisted units operate

on single-phase 240V, 50 Hz power via a 10A outlet.

Quality Assurance and

Control.

Clyde-Apac laminar flow

and HEPA filter products are manufactured in Australia under an accredited

Total Quality Management system. Please refer to our Standards

page.

Options

Prefilter in place of spigot

Alternative spigot dimensions

and orientation

TFPE configuration for exhaust

applications

‘Ultra-quiet’ variant of TFPBL

Series

Stainless-steel filter guard

On-site testing

TFP Series modules are factory-tested

and certified by a NATA-registered laboratory. Additional testing and certification

should be carried out on site prior to use, and subsequently:

After any electrical or mechanical

maintenance

After filter replacement

After re-location

At least annually

In special circumstances, e.g.

if faulty operation is suspected

Laminar Air Flow Services,

a NATA-registered laboratory and a division of Clyde-Apac, provides comprehensive

on-site maintenance, testing and certification services for safety cabinets,

laminar flow work stations, cleanrooms and HEPA filter installations. This

service is available from fully-equipped, NATA-registered laboratories

in major Australian centres.

Due to ongoing research

& development, Clyde-Apac reserves the right to modify the product

& specifications without notice.

|

Description

Description

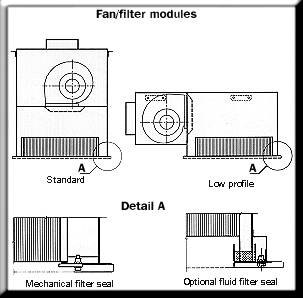

Housings.

Constructed in electro-galvanised steel with exterior finish in a special

baked enamel that has been developed for cleanroom and laboratory equipment.

Standard modules use a mechanical (gasket) filter seal, with the option

of fluid seal available on some models.Access on the underside of the module

(room side) for filter and fan service, an aerosol sample port and fan

speed controller obviates the need for access to the ceiling space.Pre-drilled

brackets are provided to facilitate suspension arrangements.

Housings.

Constructed in electro-galvanised steel with exterior finish in a special

baked enamel that has been developed for cleanroom and laboratory equipment.

Standard modules use a mechanical (gasket) filter seal, with the option

of fluid seal available on some models.Access on the underside of the module

(room side) for filter and fan service, an aerosol sample port and fan

speed controller obviates the need for access to the ceiling space.Pre-drilled

brackets are provided to facilitate suspension arrangements.